Netting Selection Guide

Selecting the proper net for your application can sometimes be a confusing process because of the many different options available. Understanding those options will help you decide which netting product is right for you.

Netting is a versatile product that has many benefits. It can be used for a variety of purposes, from sports safety, facility safety, barrier systems, to construction safety. There are different types of netting made from various materials. The mesh size and type can also vary depending on the application. Netting is often finished with an edge or border, and it is fastened in place with hardware.

Topics in this netting guide:

An Overview of Different Types of Netting

Netting comes in a variety of forms and is used for a wide range of purposes. Whether you’re looking to keep your cargo safe during transport, keep your employees safe from dangerous falls, protect equipment and personnel from falling debris, or if you need to create a barrier, there’s a type of netting that’s perfect for the job. In this guide, we’ll give a brief overview of some of the most popular types of netting so that you can make an informed purchasing decision.

Cord/Twine Netting

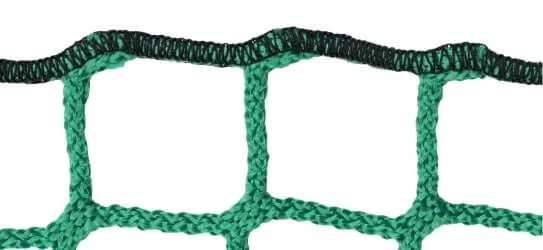

Cord netting, often referred to as twine netting, is cylindrical in shape and is made from a few typical materials such as polypropylene, polyester, and nylon. Cord thickness and mesh size can be configured in many different ways to meet the needs of your application. Cord netting is configured in two main types: Knotted and Knotless.

Cord netting is commonly used in the following applications:

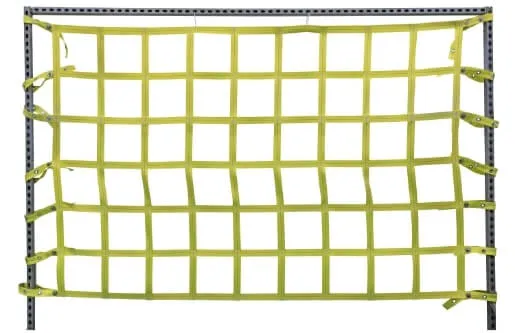

Web Netting

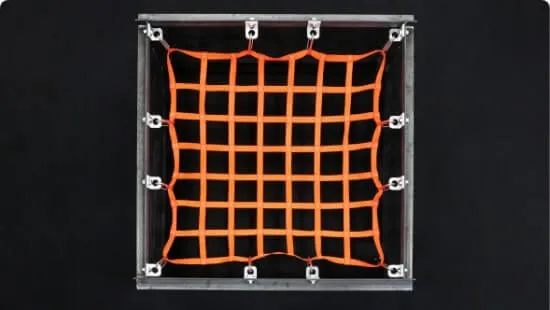

Web netting is made from interlocking strands of material, similar to cord/twine netting. Webbing is a flat material unlike cord netting, which is cylindrical. Webbing is also much stronger and more durable. It’s often used for cargo control and safety barriers.

The most common uses of web netting are:

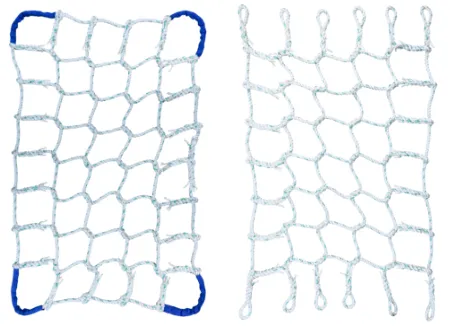

Rope Netting

Rope netting is just what the name suggests, a net made from rope material. The most common type of rope used for making rope nets is manila rope and poly dacron rope. Rope netting is great for decorative applications such as nautical themes and is also prominent on obstacle courses for climbing.

The most common uses for rope netting are:

Metal Netting

Metal netting is one of the most durable types of netting available. They are often used in industrial applications because they can withstand a lot of abuse and are very strong. Metal nets come in 3 different types:

- Steel Cable Nets

- Steel Chain Nets

- Decorative Steel Nets

Steel nets are ideal for the following applications:

- Heavy Duty Barrier Systems & Fall Protection (bridge construction and heavy duty containment)

- Heavy Duty Lifting

- Decorative

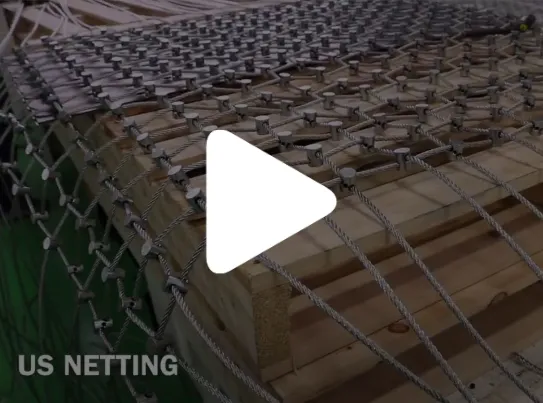

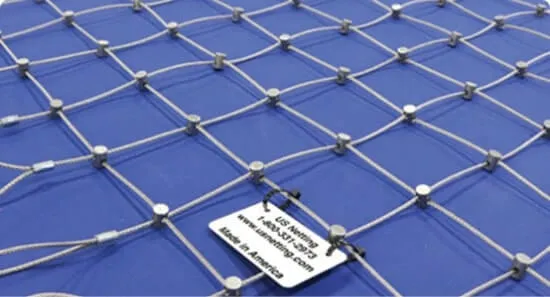

Steel Cable Netting

Steel cable nets are configured using galvanized or stainless steel cables with a variety of different cable thickness to choose from. These types of nets are often used in heavy duty applications such as bridge construction to catch falling concrete and hold back large sections of rock to prevent collapse.

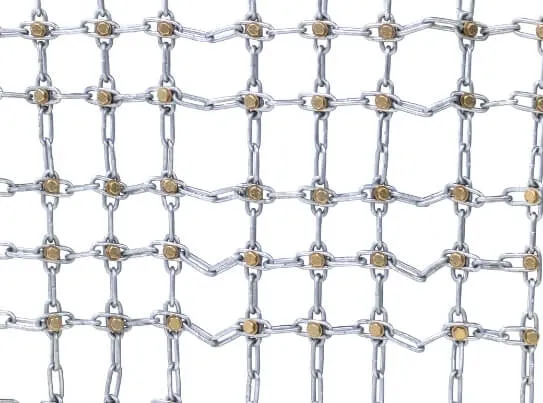

Shop Steel Cable NettingSteel Chain Netting

Steel chain nets are the most heavy duty of the metal netting lineup. Steel chains are meshed together using heavy duty bolts and washers, which provide a strength that can hold up to the most demanding applications. Often used for lifting extremely heavy materials or when extremely heavy materials need to be prevented from hazardous falls. Heavy duty steel chain nets are also a good option to help prevent injury or death from terroristic threats.

Shop Steel Chain Netting

Decorative Steel Netting

Decorative steel nets are made from thin diameter stainless steel cables and ferrules to create an attractive steel wire mesh. Decorative steel nets are often used to accentuate the architecture of a building in stairways, retail environments, and privacy areas.

Shop Decorative Steel NettingPlastic Netting

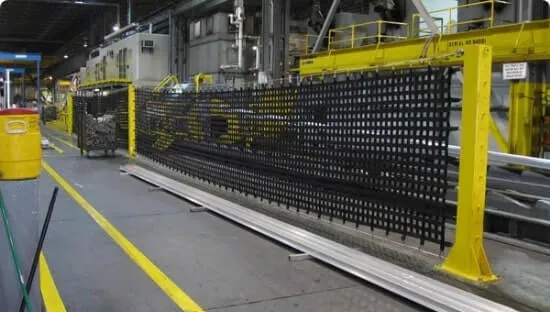

When you need to secure an area or set up boundaries for safety, few products work as well for as long as plastic netting. As a substitute for metal fencing and chicken wire, you’ll never have to worry about it rusting. Plastic mesh netting is also safer to handle than metal wire and is more cost-effective. Some of plastic netting’s advantages include:

- Lifetime durability

- Wide selection of duty ranges from fine mesh to heavy duty

- Purpose-built for different applications

- Multiple colors and mesh patterns to choose from

The major benefit of plastic netting is its versatility and wide range of use. From light duty applications such as crop protection to heavy duty applications such as elk fence, plastic netting is sure to have a configuration available for any application.

Some of the most common applications for plastic netting include:

- Safety Barrier Fence

- Deer & Elk Fence

- Agricultural

- Containment

- Snow Fence

- Pallet Rack Safety Barrier

Different Types of Netting Materials

When it comes to netting, there are a variety of different materials that can be used in its construction. The most common materials are nylon, polyester, polypropylene, Kevlar™, steel, and plastic. Each material has its own advantages and disadvantages that make it better or worse suited for specific uses. The most common materials used in netting are as follows:

- Nylon

- Polyester

- Polypropylene

- Kevlar™

- Steel

- Plastic

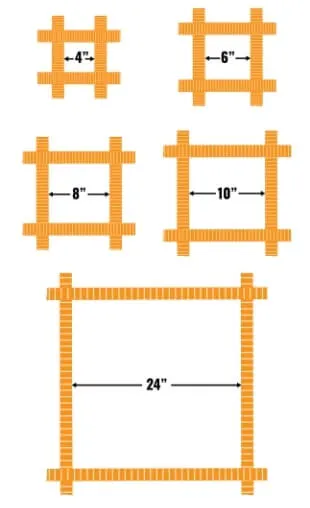

All about Mesh Sizes

Mesh size refers to the size of the openings that make up the net. The mesh size will determine the strength of the net. The smaller the mesh mesh size the stronger the net will be because it is utilizing more material. Mesh sizes are configured based on the application and also by the size of the object that is being contained. If small objects need to be contained, then a smaller mesh size is required.

Netting Types with Limited Mesh Size

With certain netting types the customizations are limited because the raw material only comes in a handful of different mesh sizes. The types of netting that have limited mesh sizes are as follows:

- Cord/Twine Netting

- Plastic Netting

- Rope Netting

Netting Types with Highly Customizable Mesh Size

If your application requires customization for larger mesh sizes the following types of netting will accommodate custom requirements:

- Web Netting

- Steel Netting

UNDERSTANDING DIFFERENT TYPES OF EDGE FINISHING/BORDERS

Edge finishing/borders are common on cord netting. When cord netting is cut to size it tends to leave loose edges on the net that are unattractive. Adding a border to the net will not only enhance the appearance of the net but also make it stronger. Some borders are stronger than others. Rope and webbing borders provide the most strength (Rope providing the strongest), while finished edges provide the least strength.

There are three main types of netting borders:

- Rope Borders

- Webbing Borders

- Finished Edge (Serged Edge)

Rope Borders

Rope borders are another type of edge finishing that uses—you guessed it—a rope to create a border around the edge of the net. Rope borders are often used for heavier duty applications because the rope provides more structure than a webbing border or finished edge. A ⅜” nylon rope is most commonly used as a netting border. Falls safety nets are a good example of a requirement for a rope border.

Webbing Borders

Webbing borders are a type of edge finishing that uses a strip of webbing that is folded over the material and sewn to create a clean, straight border around the edge of the net. Webbing borders a great for creating netting panels that have grommets punched in for easy fastening.

Finished Edges

When an item has finished edges, it means that the raw edges of the fabric have been sewn or serged together to create a clean finish. One advantage of finished edges is that they won’t fray over time like other types of edge finishes can and it gives the netting a clean look.

HARDWARE NETTING ATTACHMENT OPTIONS

When attaching netting to a structure, several tried-and-true methods make the job quick and easy. Depending on the application, one method may be better suited than another. This overview will touch on some of the most popular attachment options to help you make an informed decision about the best way to secure your netting.

The most popular hardware attachments are as follows:

- Snap Hooks

- Rings

- Cam Buckles

- Loop

AN OVERVIEW OF NETTING APPLICATIONS

Netting has a variety of applications, from fall safety to debris containment. It is a versatile and affordable solution for many needs. Let’s take a look at some of the most common netting applications.