Rope Selection Guide & Information

Searching for the right rope for your job can be overwhelming. Over the years, manufacturers have produced a variety of ropes for a variety of jobs. Each rope has unique strengths and weaknesses. Particular ropes are well suited for certain jobs and not others. Some ropes have a wide range of capabilities, but there is no “one size fits all” rope. Don’t let the variety scare you. You need the right rope for your job. Here is a guide to some of the most common ropes including their strengths, weaknesses, and which one will be right for your situation.

If you happen to be looking for rope to build a net, we have an excellent guide to netting. The guide includes rope, webbing, and all purpose netting.

Table of Contents

WHAT QUALITIES ARE YOU LOOKING FOR?

WHAT ARE YOU USING THE ROPE FOR?

Rope Material Properties and Use Cases

Polypropylene Rope

Polypropylene ropes are synthetic and possess a variety of unique qualities. Polypropylene rope is particularly suited for use around water and will not rot due to water and is resistant to mildew. This rope is also produced in a variety of colors making it a common choice for barriers at golf courses, parks or even power plants. Because polypropylene floats, it is used to designate swimming lanes in pools. Commercial fishermen commonly utilize this rope, especially in crab and lobster lines. It can also be used for buoy moorings, aquaculture, and net lines.

PROS

Dielectric/insulator, floats, water resistant, lightweight, low-cost, UV resistant, color variety.

CONS

Stretches (although this could be a positive), susceptible to friction.

Most common use:

Work around electric lines, marine applications, swimming-lane barriers.

EXTRAORDINARY QUALITIES

Dielectric ability is an important quality of polypropylene rope. Should this rope touch a live electrical wire it will not conduct the electric current. Because polypropylene rope acts as an insulator, electricians and tree workers who work around live electrical wires use polypropylene rope. When using this rope for hauling or hoisting, attention should be given to any abrasions against the rope as it can melt from friction. Polypropylene also lacks stretch memory. When stretched, it will not return to its normal size.

This rope has wide capabilities. If you need a strong rope to be used in or around water, or if you anticipate possible exposure to electricity, then polypropylene rope will be your best choice.

Manila Rope

The natural strength and all around utility of manila rope has made it the standard for quality rope. Manila rope consists of all-natural hemp fibers. This creates aesthetic appeal commonly used for decorative fences or other landscaping purposes.

Because of susceptibility to liquid absorption and UV decay, the user should be careful of sustained tension on the rope especially when exposed to the elements. Manila’s absorbing quality makes it the first choice for many physical activities that require direct handling of the rope. For purposes such as tug of war, climbing, obstacle courses, or stage rigging, manila rope absorbs perspiration providing better grip. This rope will not hazardously snap back when broken as other synthetic ropes may. For a quality natural rope that is aesthetically appealing and safe for active handling, manila rope is an excellent choice.

PROS

Visually appealing, snap-resistant, low-cost.

CONS

Not UV or water resistant, may harden or rot over long periods of time.

Most Common Use:

Pulling, decoration, landscaping, rigging.

Nylon Rope

For superior strength and remarkable stretching capabilities, nylon is the rope of choice. Stronger than both manila and polypropylene, nylon commonly finds itself pulling the heaviest loads and bearing the most weight.

Having superior strength, nylon also maintains a smooth surface and its resistance to abrasion makes it ideal for pulley systems or winches. Also, different fall protection systems or rescue line assemblies are constructed from nylon rope. Within these applications, the strength and elasticity of nylon will be most beneficial.

PROS

Strong, smooth, abrasion resistant, UV resistant.

CONS

Absorbs water, weakens in water.

Most common use:

Towing lines, anchor lines, pulleys, winches, tie-downs, fall-protection systems.

EXTRAORDINARY QUALITIES

While both manila and polypropylene are susceptible to UV damage, nylon rope is resistant to UV, chemical exposure or any other form of rot. Despite the fact that water can weaken the strength of nylon, this effect is so slight that nylon is still commonly used for mooring lines and anchor lines. In fact, nylon rope is a great choice for any tie-down because of its strength, stretch, and sustenance in any environment. The all-around durability of nylon rope makes it useful for any job in any situation.

Polyester Rope

Polyester is considered by some to be the best general purpose rope. It’s also one of the more popular choices when a tough heavy duty rope is needed.

Polyester rope is a great rope for general industrial applications as well as rigging applications. It does great in the outdoors and tough elements of nature. Can be seen being used for lines to tie down or hold back boats in marine applications.

A few uses for this rope may include: winches, dock rigging, blocking, or simple household applications. It can also be mistaken many times as Nylon with many fine details in differences. Largest difference being its resistance to chemicals.

PROS

Rot and UV resistant, retains strength when wet or dry and abrasion resistance.

CONS

Bright white color can become discolored and brown/green in marine applications.

Most common use:

Rigging, winches, general household uses. Shop Polyester Rope

Kevlar™ Rope

Few innovations in the past century have been as remarkable and useful as Kevlar™, invented in 1965 and produced by DuPont™. Among its many uses, Kevlar™ materials have been used for bullet-proof armor and flame resistant material. Kevlar™ rope is no less remarkable. Pound for pound, Kevlar™ rope is far stronger than steel and it will not rust. For this reason, Kevlar™ rope is used as mooring lines on oil rigs and ships. While nylon rope has certain elastic abilities, Kevlar™ rope has very low stretch, making it an excellent choice when complete stability is needed.

PROS

Strongest rope, freeze resistant, flame resistant, chemical resistant, water resistant, stretch resistant, cut resistant, UV Resistant Coating.

CONS

Not immune to damage.

Most common use:

Winch lines, mooring lines, helicopter slings, temperature extreme situations.

EXTRAORDINARY QUALITIES

Because of its polymeric properties, Kevlar™ material is susceptible to UV light and should not be permanently exposed to UV rays. Unlike any other rope, Kevlar™ rope is flame resistant. This rope can resist temperatures 500° F before it begins to weaken, and Kevlar™ will only strengthen when exposed to subzero temperatures.[1]

One should be aware of any signs of wear on Kevlar™ rope, as the integrity of the rope can be more seriously compromised than the damage makes it appear. Kevlar’s qualities are best demonstrated in extreme temperature conditions, or any time sheer strength is required.

| Strength | Manila | Nylon | Polyester | Polypropylene | Polyethylene | Kevlar™ 1* |

|---|---|---|---|---|---|---|

| Breaking Tenacity(grams/denier) | 5.0-6.0 | 7.0-9.5 | 7.0-9.5 | 6.5 | 6.0 | 18-26.5 |

| Wet Strength vs Dry | Up to 120% | 85-90% | 100% | 100% | 100% | 95% |

| Shock-load Absorption Ability | Poor | Excellent | Good | Very Good | Fair | Poor |

| Weight | Manila | Nylon | Polyester | Polypropylene | Polyethylene | Kevlar™ 1* |

| Specific Gravity | 1.38 | 1.14 | 1.38 | 0.91 | .95 | 1.44 |

| Floats | No | No | No | Yes | Yes | No |

| Elongation | Manila | Nylon | Polyester | Polypropylene | Polyethylene | Kevlar™ 1* |

| Percent at Break | 10-12% | 18-25% | 12-15% | 15-25% | 15-25% | 1.5-3.6% |

| Creep(extension under sustained load) | Very Low | Moderate | Low | High | High | Very Low |

| Effects of Moisture | Manila | Nylon | Polyester | Polypropylene | Polyethylene | Kevlar™ 1* |

| Water Absorption of Individual Fibers | Up to 100% | 2-8% | < 1% | None | None | 3.5-7.0% |

| Dielectric Properties | Very Poor | Poor | Good | Excellent | Excellent | Poor |

| Degradation | Manila | Nylon | Polyester | Polypropylene | Polyethylene | Kevlar™ 1* |

| Resistance to UV in Sunlight | Good | Good | Excellent | Poor(black is best) | Fair(black is best) | Fair |

| Resistance to Rot and Mildew | Poor | Excellent | Excellent | Excellent | Excellent | Excellent |

| Storage Requirements | Dry Only | Wet or Dry | Wet or Dry | Wet or Dry | Wet or Dry | Wet or Dry |

| Rope Abrasion Resistance | Manila | Nylon | Polyester | Polypropylene | Polyethylene | Kevlar™ 1* |

| Surface | Fair | Very Good | Very Good | Good | Good | Fair |

| Internal | Fair | Excellent | Excellent | Good | Good | Poor |

| Thermal Properties | Manila | Nylon | Polyester | Polypropylene | Polyethylene | Kevlar™ 1* |

| Melts at | Does not melt, Chars at 350º | 420-480º | 490-500º | 330º | 275º | 800º begins to decompose |

| Resistance 3* | Manila | Nylon | Polyester | Polypropylene | Polyethylene | Kevlar™ 1* |

| Resistance to Acids | Poor | Fair | Good | Good | Excellent | Fair |

| Resistance to Akalis | Poor | Very Good | Poor | Good | Excellent | Fair |

| Resistance to Oils and Gas | Poor | Very Good | Good | Good | Very Good | Very Good |

STYLES OF ROPE

Ropes are not only made with a variety of materials (manila, polypropylene, nylon, Kevlar™, etc.), but any given rope can have different styles of braid or twist. Twisted rope appear in the form of a spiral and are created by twisting at least three strands of yarn in alternate directions. This alternation prevents the rope from unwinding, while also making it easy to splice. Because of the speed of their manufacturing, twisted ropes tend to be less expensive.

Braided ropes take on a rounded form and are generally smooth. This feature allows them to be used in high-friction situations like winches and pulleys. During the longer and more expensive process of braiding, several fibers pass above, below and around each other. This relatively recent innovation provides a rope that will not twist, but cannot be spliced.

Several different ways of braiding provide different qualities. Solid braid ropes are a complex braid that may have a filler core. They have high elongation but less strength. Diamond braids rotate fibers over and under one another in opposing directions. A filler is usually placed in the center of this rope giving it moderate strength. Double braided rope can actually be understood as a rope within a rope. One braid is formed over another braid to share the load evenly. Double braided rope is a favorite for boaters, but should be used with caution in manufacturing situations.

WORDS OF CAUTION WHEN WORKING WITH ROPE

Use of Working Loads

Because of the wide range of rope use, rope condition, and exposure to the various factors affecting the rope, it is impossible to make blanket recommendations as to the correct choice of rope to use. However, we have provided the tensile strength for each diameter and type of rope. These strengths are based on tests of new and unused rope, with appropriate splices. Proper choice, care, and inspection of the rope are essential for reasonably safe use of the rope. Consult your cordage vendor for proper use.

Dynamic Loading Voids Normal Works Loads

Dynamic Loading occurs when rope is subjected to sudden or extreme stress. Figures given as working loads are void if rope has been subjected to dynamic loading, high temperatures, long periods of load, extreme stress, improper use, or storage.

To lash, tie a clove hitch through each mesh.

This will prevent the rope from unraveling if it should become compromised.

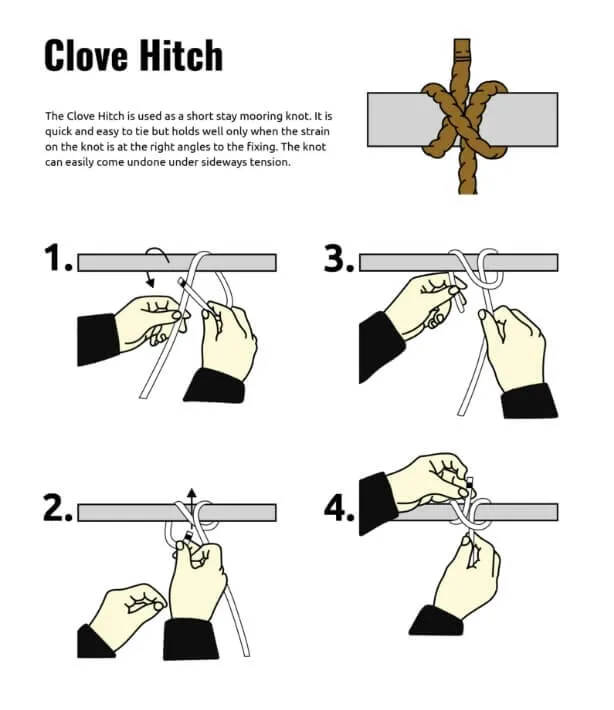

The clove hitch is used as a short stay mooring knot. It is quick and easy to tie but holds well only when the strain on the knot at right angles to the fixing. The knot can easily come undone under sideways tension.

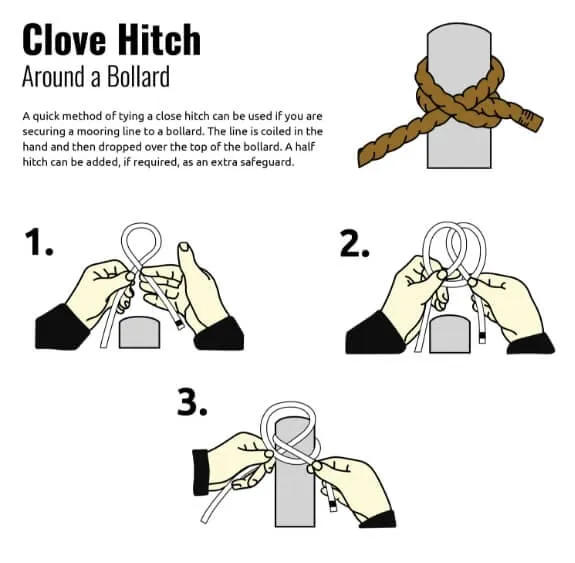

Clove hitch around a bollard

A quick method of tying a clove hitch can be used if you are securing a mooring line to a bollard. The line is coiled in the hand, as shown below, and then dropped over the top of the bollard. A half hitch can be added, if required, as an extra safeguard.

Effect of Temperature on Tensile Strength

The tensile strength charts apply to ropes tested at normal room temperature (70°F). Ropes have lower tensile strength at higher temperatures. Continued exposure at elevated temperatures causes permanent damage.

WARNING! MISUSE OF ROPES COULD RESULT IN SERIOUS INJURY

Rarely can you walk in to your local hardware store and find a full selection of rope types and sizes. Online stores like US Netting not only offer a full selection of all types and diameters of rope, but they will cut to length the rope you need! Matching the right rope to the right job will not only make the job easier, but it will also make the job safer.

Paul Galla, President

US Netting

https://www.usnetting.com

SOURCES:

[1] http://en.wikipedia.org/wiki/Kevlar

KNOT GUIDE

Knots are handy things. For many people, knots play a crucial role in their work or recreation. They may even save a life! For connecting, lifting, securing or towing, you will need to learn the names of different knots, and when to use them

Square Knot (AKA: Reef Knot)

A very quick knot to tie, the square knot is used to join two ropes together in a simple and effective way. However, you should be aware that this knot is not reliable for heavy weights or critical situations. The square knot has been used for centuries to join two ends together for bandages or shoelaces or belts. The Boy Scouts require skill with this knot for general purposes.

common use:

- Fishing

- Hunting

- Lashing

- Boating

- Macrame

- General Use

Bowline Knot

The bowline was originally used in a marine setting (as are many knots), but has proved itself useful in a wide range of situations. The qualities of this knot are its simplicity, strength and resistance to jamming. Because of the intentionally open loop in the completed knot, the bowline can be slung over a post or other object after it has been tied. This knot can also be tied after the rope has been passed through a ring. You should be cautious as the knot can become undone if it is shaken or jostled.

common use:

- Boating

- Safety

Overhand Knot

A simple knot with the most basic tying steps. Used mainly as a stopper in such applications like climbing ropes or to stop the rope from falling out of a pulley system.

common use:

- Basic Stopping

- Lashing rope ends

- Helps prevent fraying

Slip Knot

The slip knot is used to slid and tighten around a post, tree, or hitch. This knot is great due to the fact that it tightens under loads. Many people also consider the slip knot as a noose. In this term it is not due to the way it is tied.

common use:

- Hunting

- Camping

- Temporary stopping or holding

- General use

Sheet Bend (AKA: Weaver's Knot)

The Sheet bend is best used to join two ropes of unequal sizes. This is great for broken splices or just needing a few extra feet to pull down that branch.

common use:

- Hunting

- Camping

- Temporary stopping or holding

- General use

Tying It All Together

These are some of the more common knots used for work or play. An emergency situation is not the time to try to tie one of these knots. It is best to be prepared by practicing these knots before you need them. Many knot tying guides are available. Find one with good illustrations and practice with inexpensive rope or scraps. You will then have the confidence to take full advantage of rope and the many situations you are likely to encounter.

Paul Galla,

President USNetting.com