Conveyor Netting

Conveyor Netting Guide

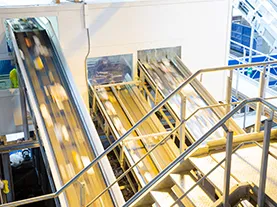

The rise in construction of warehousing and distribution facilities has led to a massive increase in conveyor systems. Most conveyor systems require a safety net installation to provide personnel and equipment with the proper safety conditions so they don’t get hurt or damaged from an item falling off of the conveyor.

Designing a safety net for your conveyor system can often be confusing and this guide is to help you design a simple yet effective conveyor net for your conveyor system.

Mount Multiple Nets Together For Long Runs

We often get requests from organizations to fabricate very long (in some cases 1000’) conveyor safety nets. We advise customers not to purchase very long runs of conveyor net because they are very hard to handle due to the weight and difficult to install. Some customers may also try to order continuous netting for long runs and cut in the field. We also advise against this because you end up with a seam that does not have a rope border on either end of the net, which diminishes the strength of the system.

In lieu of long conveyor netting (anything over 50’) we advise our customers to purchase shorter panel sizes and hook them together using snap hooks. All of the conveyor nets we provide come with a rope border and snap hooks (every 4’) pre-installed. This method makes it very easy to handle and install the conveyor safety nets. Most of the systems we see have steel cabling to serve as the frame for the net, therefore, snap hooks make it very easy to attach the net to the frame and at the seams.

The diagram below depicts how a typical conveyor net system is installed using our fabricated panels.

Light Duty Conveyor Netting

Light duty conveyor netting is used in a variety of industries to protect workers from light debris and falling objects. Made from a tough, yet light-weight material, light duty conveyor netting is designed to be installed quickly and easily. This type of netting is used in a variety of industries, including food processing, pharmaceuticals, electronics, and more. In addition to protecting workers from falling objects, light duty conveyor netting can also help to keep light materials from spilling onto the ground or becoming tangled in machinery. As a result, it is an essential safety measure in many workplaces.

Heavy Duty Conveyor Netting

Heavy Duty Conveyor netting is an essential component of any heavy duty conveyor system. It helps to keep products securely in place while being transported, preventing them from becoming damaged or dislodged. In addition, heavy duty conveyor netting helps to protect workers from being injured by moving parts or falling product. When selecting conveyor netting, it is important to choose a heavy duty option that is able to withstand the weight and force of the products being conveyed. This will help to ensure that the netting lasts for a long time and does not need to be frequently replaced. Ultimately, heavy duty conveyor netting is an important part of keeping a safe and efficient conveyor system when heavy products are being conveyed.

Heavy Duty Conveyor Netting w/ Debris Liner

Heavy duty conveyor netting with debris liner is critical for preventing injuries and product damage when dealing with items that may fall through the mesh openings. The netting is placed over the conveyor belt to catch any debris that may fall off during the sorting process. The debris liner helps to protect the belt from being damaged by the heavy debris. Without the heavy duty conveyor netting with debris liner, workers would be at risk of being hit by falling debris, and the conveyor belt would be damaged. The heavy duty conveyor netting with debris liner is a crucial part of keeping people and equipment safe when dealing with parts and products that are dangerous.